A major milestone for solid-state batteries

Solid-state batteries have long been hailed as the future of electric vehicles, offering huge advantages over traditional lithium-ion technology. Now, Stellantis and Massachusetts-based Factorial Energy have validated a new semi-solid-state battery cell, moving the dream closer to reality.

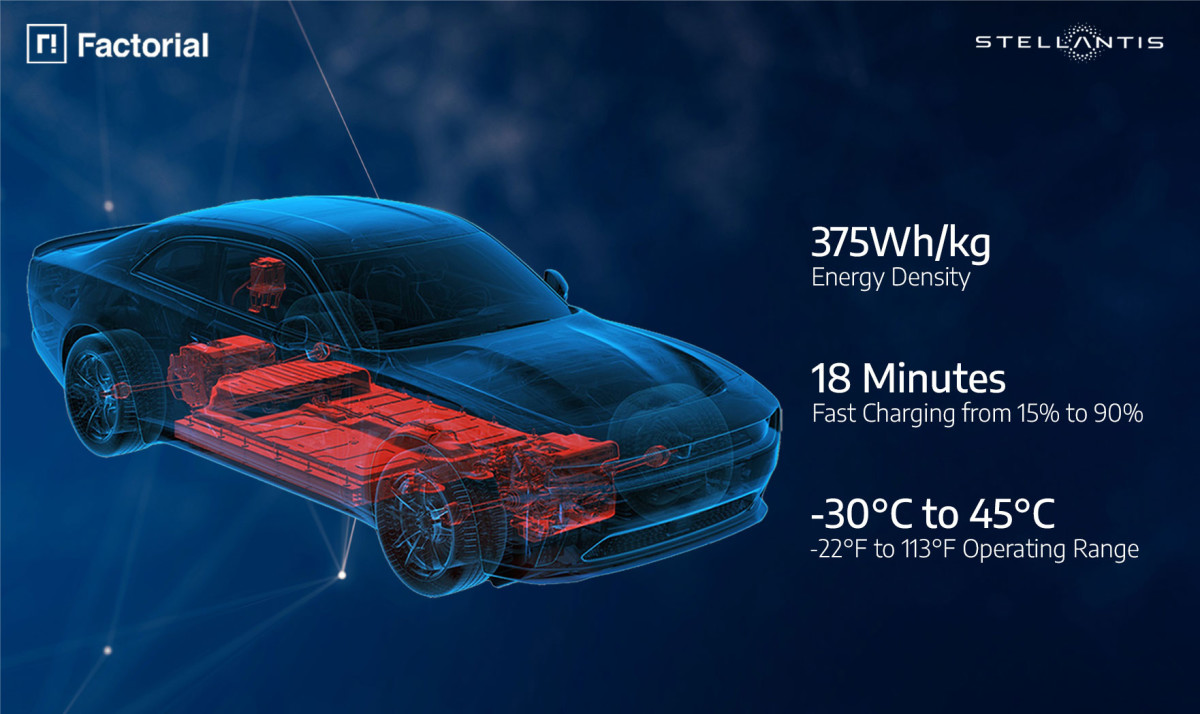

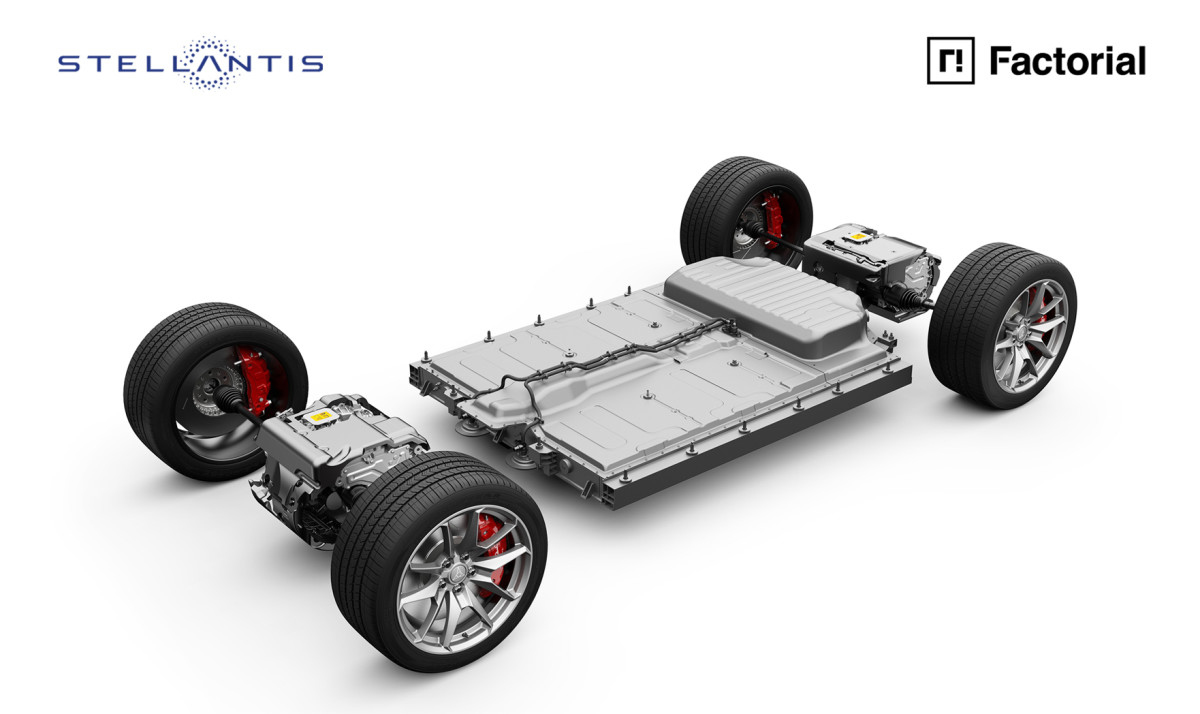

The battery boasts an impressive energy density of 375 watt-hours per kilogram, well above today’s industry average of 200-300 Wh/kg. Charging from 15-90% takes just 18 minutes at room temperature, and the cells maintain performance in temperatures as low as -22°F. These features could significantly improve EV range, charging convenience, and cold-weather reliability. To prove the technology in the real world, Stellantis will install these cells in a demonstration fleet of Dodge Charger Daytona EVs starting in 2026.

Why it matters for EVs

Beyond faster charging and longer range, the semi-solid-state battery could revolutionize vehicle weight. Factorial estimates that the new batteries could shave 200 pounds just from the battery pack alone. Thanks to fewer structural and thermal management components needed, total vehicle weight savings could range from 500 to 2,000 pounds.

Factorial

For an electric muscle car like the Charger Daytona, which currently tips the scales at around 5,800 pounds, this could be a game-changer for performance. Lighter vehicles aren’t just faster, they’re also more efficient and cheaper to produce over time. Every pound shed could save about $5, meaning potential cost savings of up to $10,000 per vehicle.

Production challenges and costs

Despite the technical success, production remains a significant challenge. Factorial CEO Siyu Huang candidly described the journey as “production hell” in an interview with InsideEVs, marked by high scrap rates and material difficulties.

Factorial

Cost is another major obstacle. Huang noted that small-scale versions of these solid-state cells can be 10 to 30 times more expensive than conventional lithium-ion cells. While she is optimistic that mass manufacturing will drive costs down, that reality is still a few years away.

In the meantime, Factorial’s cells represent an important interim step. These polymer-based semi-solid-state batteries are not fully solid-state yet, but they help stabilize the anode — a key area of degradation in traditional batteries — setting the stage for true all-solid-state batteries in the future.

Final thoughts

Dodge

Factorial’s partnership with Stellantis and its earlier work with Mercedes-Benz show the growing interest among major automakers in solid-state solutions. If scalability and costs can be tackled, this new generation of batteries could address many of the lingering concerns around EV range, charging times, safety, and durability, all with a single technology. The real-world testing with the Dodge Charger Daytona will be an important test. If successful, it could mark a turning point not just for Stellantis but for the entire EV industry.